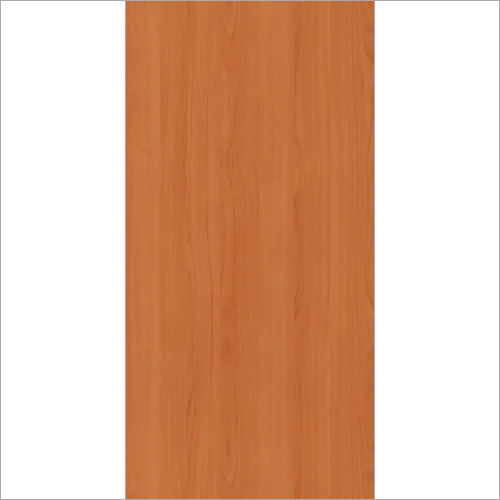

Plain MDF Board

Price 800 INR/ Square Foot

Plain MDF Board Specification

- Size

- 8x4 & 8x6

- Thickness

- 20 Millimeter (mm)

Plain MDF Board Trade Information

- Minimum Order Quantity

- 1000 Square Foots

- FOB Port

- NEW DELHI

- Payment Terms

- Cash Against Delivery (CAD)

- Supply Ability

- 2000 Square Foots Per Day

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- normal

- Main Domestic Market

- North India

- Certifications

- as per ISI

About Plain MDF Board

Plain MDF Boards are used mainly utilized for indoor applications. They have good moisture resistance and are appreciable for their decorative make. These are used to make cabinets of shiny and strong surface. Plus, these are used to make furniture, cabinetry and others. Plain MDF Boards are appreciable for their good fire resistance and soundproofing attributes. Thickness of the board is 1.9 to 25 Millimeter (mm). Applications are Application Wall Decoration, Cabinet, Floor, Countertop, Ceiling Decoration, Kitchen, Furniture Decoration, and others.

Highly Precise and Durable

Crafted with advanced techniques, these MDF boards offer a microscopic tolerance of 0.001 mm, ensuring uniformity across every sheet. Their density and structural integrity make them perfect for detailed finishing in carpentry, cabinetry, and modular furniture projects.

Superior Glue Technology

The combination of UF and melamine glues imbues each board with formidable adhesive strength and improved resistance to moisture, supporting longer life in humid conditions. These boards are exceptionally suited to both residential and commercial projects.

FAQs of Plain MDF Board:

Q: How is the Plain MDF Board manufactured?

A: Our Plain MDF Boards are produced using high-quality wood fibers bonded together under intense pressure with urea-formaldehyde (UF) and melamine glues, ensuring a dense, uniform composition and smooth surface finish.Q: What are the available sizes and thickness options for the MDF board?

A: These boards come in standard sizes of 4x8 feet, 8x4 feet, and 8x6 feet, with a range of thickness options from 1.9 mm up to 25 mm, including a popular 20 mm variant, catering to varied construction and design requirements.Q: When should I choose MDF boards with melamine glue over regular MDF?

A: Opt for MDF boards with melamine glue when you need enhanced moisture resistance, particularly for environments that may be exposed to higher humidity, such as kitchens, bathrooms, or commercial interiors.Q: Where can these MDF boards be used?

A: These boards are ideal for furniture manufacturing, interior paneling, partitions, doors, wall claddings, and cabinetry due to their consistent density and smooth, flat edges.Q: What is the installation process for these MDF boards?

A: MDF boards can be cut, drilled, and shaped using standard woodworking tools. Proper edge sealing and finishing are recommended to maintain longevity, particularly for areas exposed to moisture.Q: How does the boards density and tolerance benefit users?

A: A high density of 720 kg/m3 ensures structural strength, while the extremely low tolerance of 0.001 mm provides precise fit and finish, minimizing gaps and ensuring high-quality outcomes in detailed woodwork projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Laminated MDF Boards Category

Straight Wenge MDF Board

Price 39.01 INR / Piece

Minimum Order Quantity : 50 Square Foots

Size : 8x4, 8x6

Material : Wood

Usage : Indoor

Plywood Type : other, MDF Board

Pre Laminated MDF and HDHMR

Price 42 INR / Piece

Minimum Order Quantity : 50 Square Foots

Size : 8X4

Material : Wood

Usage : Wall panel, Decoration, Indoor

Plywood Type : other, Pre Laminated MDF and HDHMR

Prelaminated Particle Board

Price 39.01 INR / Piece

Minimum Order Quantity : 25 Square Foots

Size : 8X4, 8X6

Material : Wood

Usage : Wall panel, Decoration, Indoor

Plywood Type : other, Prelaminated Particle Board

Oxford Cherry MDF Board

Price 39.01 INR / Piece

Minimum Order Quantity : 50 Square Foots

Size : 8X4 8X6

Material : Wood

Usage : Decoration, Indoor, Wall panel

Plywood Type : other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS